- HOME

- News

- About Daiwa

Our Business

Recruit

- Contact Us

- Privacy Policy

- Site Map

Products

Products

-

NX SystemBased on "Simple is the Best" motto, we constructed New Daiwa System, NX System designed to advance in strengthening the rust preventative function.Magazine Rack Type Loader

(Product No.: NX201)

Product Name Magazine Rack Type Loader

(Product No.: NX201)Specifications PCB size Min. 510mm(W)(fixed)×340mm(L)

Max. 510mm(W)(fixed)×510mm(L)Thickness 0.4mm~2.3mm Capacity 6 PCBs/min Features This is designed to take a PBC out from its magazine rack and load it onto the production line. The magazine rack can stock PCB with standing separately not to touch each other. -

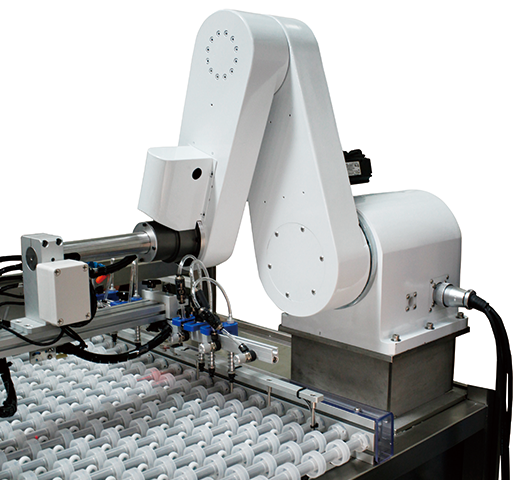

D Rack Type Loader (3-anxis robot type)

(Product No.: NX761)

Product Name Magazine Rack Type Loader

(Product No.: NX201)Specifications PCB size Min. 300mm(W)(fixed)×300mm(L)

Max. 610mm(W)(fixed)×610mm(L)Thickness 0.03mm~3.2mm Capacity 7 PCBs/min Features This system can load thin PCB (less than 0.1mm), one by one from D-rack to the line.

This product provides 3-axis loading robot, and this is the first original loader with 3-axis robot in Japan.

This robot enables to carry various PCB sizes as well as various shapes of rack.

【Available Rack】

・D rack (Thin PCB), L rack (Normal to thick PCB), Flat tray (stacking) etc.

For more requests, please contact us. -

D Rack Type Unloader (NX817)

Product Name D Rack Type Unloader (NX817) Specifications PCB size Min. 300mm(W)(fixed)×300mm(L)

Max. 610mm(W)(fixed)×610mm(L)Thickness 0.03mm~3.2mm Capacity 6 PCBs/min Features This unloader is Daiwa's original product that can unload thin PCB less than 0.1mm.

It receives PCB from the line and stocks it to D-rack.

D rack for NX817 is designed to stock thin PCBs with less sliding.

■ Other Available Products

・Magazine Rack Type Unloader (NX501)・D Rack Type Loader (NX715)

・AL-Rack for Thin Panel Type Loader (NX239)

・AL-Rack for Thin Panel Type Unloader (NX256)

・Horizontal Type Loader (NX101)

・Horizontal Type Unloader (NX102)

-

VF SeriesVF series are the standard types of material handling systems.L-Rack Type Unloader

(Product No.: VF244)

Product Name L-Rack Type Unloader (Product No.: VF244) Specifications PCB size Min. 250mm(W)(fixed)×250mm(L)

Max. 610mm(W)(fixed)×610mm(L)Thickness 0.1mm~3.2mm Capacity 6 PCBs/min

(High speed type: 8 PCBs/min)Features L-Rack Type Unloader receives one PCB by its arm and places it to portable rack (L rack).

It can unload a wide range of thin standable PCBs and thick ones.

This portable rack is called L rack.

The combination of L-Rack Type Loader and Unloader made Daiwa know in this industry.

■ Other Available Products

・L-Rack Type Loader (VF228)・Stock Conveyor (Buffer Conveyor)(VF453)

・Wicket Type Conveyor (VF160)

・AL-Rack for Thin Panel Type Loader (VF239)

・AL-Rack for Thin Panel Type Unloader (VF256)

・Turn Conveyor (L turn Conveyor・T turn Conveyor)(VF153)

・Center Alignment Conveyor (VF155)

・90°Panel Direction Change Conveyor (VF800)

・90°Panel Rotation Conveyor (VF900)

・L-Rack with Slip Sheet Type Loader (VF229)

・L-Rack with Slip Sheet Type Unloader (VF245)

-

W SeriesW System loader loads two PCBs with a slip sheet between them and remove it to the stockyard.

The unloader receives PCB from production line and place a slip sheet onto PCB.W-system Unloader with Slip Sheet

(Product No.: WU318)

Product Name W-system Unloader with Slip Sheet

(Product No.: WU318)Specifications PCB size Min. 250mm(W)×250mm(L)

Max. 610mm(W)×610mm(L)Thickness 0.03mm~3.2mm Capacity 6 PCBs/min Features As with D rack, W rack can perform to stock thin PCB less than 0.1 mm.

The conveyor receives PCB from production line and it tilts to place PCB in W rack.

This system can receive PCB and sheet without using vacuum pads so that it allows to handle PCBs with less touches.

■ Other Available Products

・W-System Loader with Slip Sheet (WL318)-

LX SeriesAuto Loader (rotary type)

(Product No.: LX423)

Product Name Auto Loader (rotary type)(Product No.: LX423) Specifications PCB size Min. 250mm(W)×250mm(L)

Max. 610mm(W)×610mm(L)Thickness 0.05mm~3.2mm Capacity Time for exchanging PCB: 5.5 minutes (fastest) Features This loader automatically places one PCB onto the stage of production/inspection process(ex. exposure or intermediate inspection line), and take it out after it is produced/inspected to next process.

These processes are currently performed by operators, but our system enables to automize them completely.

The PCB transfer has two vacuum hands(upper and lower sides) so that it can carry two PCBs directly.

One hand loads PCB onto the stage of production/inspection line, it rotates 180°, and another hand takes out and transfer to next process.

■ Other Available Products

・Auto Loader (straight type)(LX393)・Auto Loader (type R)(LX607)

-

BR SeriesBrush type PCB Cleaner

(Product No.: BR220)

Product Name Brush type PCB Cleaner (Product No.: BR220) Specifications PCB size Min. 250mm(W)×250mm(L)

Max. 610mm(W)×610mm(L)Thickness 0.4mm~3.2mm Capacity 6 PCBs/min Features A brush made of special fiber gets dust off, and then a blower sucks the dust for collection.

This cleaner is intended for PCB that are 0.4 mm or more in thickness. It is useful for cleaning PCB having an irregular surface such as pattern-formed PCB.

■ Other Available Products

・Buff-type cleaner for thin PCB (BR330) 0.06~0.4mm-

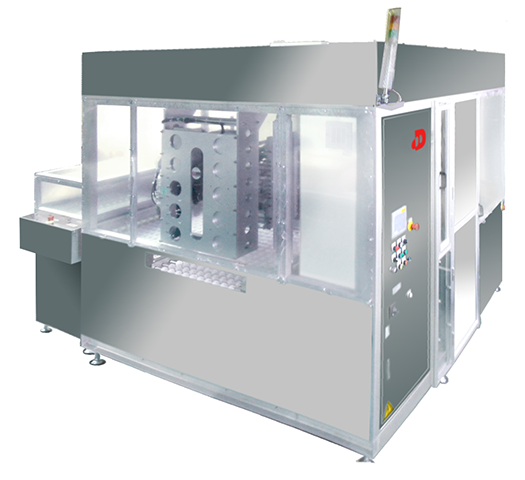

Exposure SystemFully Automatic Double-Sided Simultaneous Exposure Machine

(Product No.: DAE-2900)

Product Name Fully Automatic Double-Sided Simultaneous Exposure Machine(Product No.: DAE-2900) Specifications Light Source Short Arc Lamp 5kW×2

UV-LED Unit×2

Metal Halide Lamp 7kW×2Panel Size 660㎜×558mm~330㎜×300㎜(26"×22"~13"×11.8") Throughput 9.5sec.(Including a 2sec.Wait for Suction)+Exposure Time Features Achieved high productivity by the latest transport and vacuum contact mechanism and the optical design. Equipped with the high accuracy by high rigidity alignment mechanism. -

High Accuracy Automatic Exposure System for Solder Resist Use

(Product No.: DAE-2700)

Product Name High Accuracy Automatic Exposure System for Solder Resist Use(Product No.: DAE-2700) Specifications Light Source Metal Halide Lamp 12kw×2

Short Arc Lamp 8kw×2Panel Size (G)635㎜×535㎜~330㎜×300㎜(25"×21"~13"×11.8")

(W)660㎜×558㎜~330㎜×300㎜(26"×22"~13"×11.8")Throughput 9.5sec.(Including a 2sec.Wait for Suction)+Exposure Time Features Full automatic contact exposure system for solder resist achieved high accuracy and high productivity. -

High Accuracy Full Automatic Exposure System for Pattern Use

(Product No.: DAE-2500)

Product Name High Accuracy Full Automatic Exposure System for Pattern Use(Product No.: DAE-2500) Specifications Light Source Short Arc Lamp 5kW×1

UV-LED Unit×2Panel Size (G)635㎜×535㎜~330㎜×300㎜(25"×21"~13"×11.8")

(W)660㎜×558㎜~330㎜×300㎜(26"×22"~13"×11.8")Throughput 9.5sec.(Including a 2sec.Wait for Suction)+Exposure Time Features Full automatic contact exposure system achieving high intensity, accuracy and productivity. -

Full Automatic Exposure System for High-End PWB

(Product No.: DAE-2031B)

Product Name Full Automatic Exposure System for High-End PWB(Product No.: DAE-2031B) Specifications Light Source Short Arc Lamp 4kW×2(PT)

Short Arc Lamp 8kW×2(SR)Panel Size (G)635㎜×535㎜~330㎜×330㎜(25"×21"~13"×13")

(W)660㎜×558㎜~330㎜×330㎜(26"×22"~13"×13")Throughput (Whole Area Exposure)11.5sec.(Including a 2sec.Wait for Suction)+Exposure Time

(Partition Exposure)7.5sec.(Including a 2sec.Wait for Suction)+Exposure Time×Partition Numbe+4sec.Features High-end contact exposure system, having collimated optical system, partition exposure shutter, high intensity lamp, temperature/humidity control unit and cleaning function. -

Manual Simultaneous Double-Sided Exposure System

(Product No.: DME-680GW)

Product Name Manual Simultaneous Double-Sided Exposure System(Product No.: DME-680GW) Specifications Light Source Metal Halide Lamp 7kW×2 Exposure Area 610mm×810mm(24"×32") Uniformity of Intensity 80% (Min / Max *100%, 25-Point Measurement Average Value) -

Manual Simultaneous Double-Sided Parallel Exposure System

(Product No.: DME-1201)

Product Name Manual Simultaneous Double-Sided Parallel Exposure System(Product No.: DME-1201) Specifications Light Source Short Arc Lamp 5kW×1 Exposure Area 610mm×610mm(24"×24") Uniformity of Intensity 80% (Min / Max *100%, 25-Point Measurement Average Value) -

UV Conveyor

(Product No.: DUC-2300)

Product Name UV Conveyor(Product No.: DUC-2300) Specifications Light Source Metal Halide Lamp 8.4kW×3 Lamp Input 120W/cm 80W/cm Effective Irradiation Width 600mm -

Double-Sided UV Conveyor

(Product No.: DUC-2215)

Product Name Double-Sided UV Conveyor(Product No.: DUC-2215) Specifications Light Source Metal Halide Lamp 8.4kW×3 Lamp Input 120W/cm 80W/cm Effective Irradiation Width 600mm

Accessory

AL-Rack for Thin Panel Type

AL-Rack for Thin Panel Type

(ARB-220) Magazine Rack (NX901)

Magazine Rack (NX901) D-Rack (RD003)

D-Rack (RD003) D-Cart (WD002)

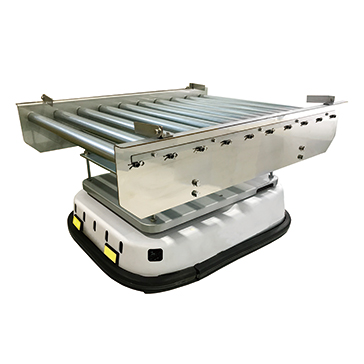

D-Cart (WD002) Automatic Carrier Cart (WG101)

Automatic Carrier Cart (WG101)